HBF Techniek has experience with multiple projects across various industries. Below, a selection of succesfully completed projects by the founder of HBF Techniek can be found.

Process installations

Developing process installations to quickly and extremely accurately mix a product related to the foundry business. A new measurement system was developed and implemented in these installations which have been engineered to be universally deployable. The software engineering and supervision, P&ID and mechanical drawings for this installation were all part of the scope for this project. Several installations have been deployed across the world, and are being monitored remotely.

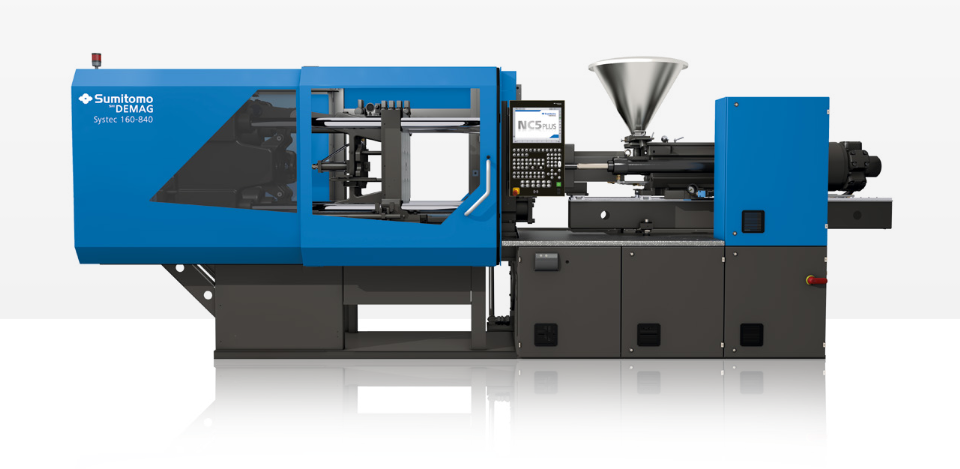

Receiver systems

To retrieve injection moulded products, several receiver systems were developed according to the custom requirements of the customer. Where possible, simple movements and solutions were chosen. Where this was not possible, motion profile analyses were made of the necessary dynamic movements, to achieve the desired cycle times.

Internal transport

A system for the internal transport of plastic products through a factory over hundreds of meters has been engineered and realized. Cost and reliability were the most important requirements. After transport, the products had to be separated again to be presented individually to the assembly machine. For this purpose a de-nester which is inline in the conveyer system was developed.

stacking

At a customer who produces corrugated roofing sheets, excessive wear occurred on the bearings of the mechanism that stacks the corrugated sheets after production. To provide a solution, extensive research has been conducted into the failure mode of the bearings, and a new solution has been carefully designed and produced, which has improved the service life of the system from a few weeks to a few years!

Grinding machine

For a customer who performs surface treatments on stainless steel, a grinding machine has been developed that fully automates the manual process of grinding stainless steel strips. The machine can grind the sides of all necessary thicknesses and lengths of strips, even strips with arbitrary contours can be ground without adjustment of the machine. This relieves the employees of physically demanding work and the customer has realized more capacity for this operation..

various revision & optimalisation

For various customers, failure-prone or expensive parts of machines have been overhauled or redesigned to increase operational reliability or to realize more capacity or quality.